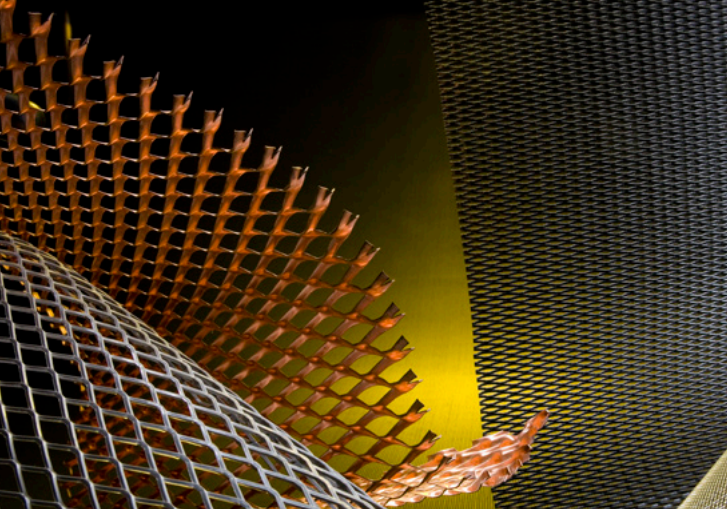

The term “expanded metal” refers to sheet metal that has been cut, stretched, and shaped into a material that resembles a metal mesh and has regular patterns, most frequently diamond shapes. There are numerous residential and commercial applications for expanded metal. Expanded metal is more durable and adaptable than many other types of sheet metal. Stainless steel, brass, or aluminum is used to make expanded metals. They are strong, lightweight, and chemically resistant. Several objects, including conveyor pathways, braai grids, and fencing, can be made with expanded metal. Read More…

At Zauderer Associates, Inc., we specialize in providing high-quality expanded metals tailored to meet diverse industrial needs. Our extensive range of expanded metal products offers versatile solutions known for their strength, durability, and reliability. Leveraging advanced manufacturing techniques, we supply precision-engineered materials ideal for applications such as filtration, security...

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

At Expanded Solutions L.L.C., we take pride in producing high-quality expanded metals that serve as durable, versatile solutions for a wide range of applications. We engineer our products to meet demanding performance requirements in industries such as construction, filtration, security, and manufacturing. By expanding metal sheets through precision cutting and stretching processes, we create...

More Expanded Metal Sheet Manufacturers

The Process of Manufacturing Expanded Metal Sheets

Expanded metal sheets are widely used in industrial, architectural, and commercial applications for their superior strength-to-weight ratio, versatility, and open area that allows for air, light, and moisture passage. The manufacturing process of expanded metal sheet begins with a solid sheet or coil—often made from materials such as stainless steel, aluminum, carbon steel, or brass. This sheet is simultaneously slit and stretched using a precision die, producing a uniform mesh pattern of diamond-shaped openings. The process avoids waste since the metal is not punched out, but expanded, making it both cost-effective and environmentally friendly.

During expansion, alternating patterns are used to cut the metal sheet before stretching it out like an accordion. This process creates a rigid, one-piece construction that enhances the overall strength of the sheet. Expanded sheet metal is often used to filter air or water, as the interconnected strands form a barrier while allowing flow. Metals like brass, aluminum, and stainless steel are favored for their high durability, corrosion resistance, and long service life in challenging environments.

Key Benefits of Expanded Metal Sheet Manufacturing

- Efficient use of raw materials, reducing waste compared to perforated sheet metal

- Increased tensile strength and rigidity due to the integral design

- Customizable mesh sizes, thicknesses, and materials for a range of industrial needs

- Cost savings on material and fabrication, as there is no welding or joining required

- Enhanced slip resistance, making it ideal for walkways, platforms, and safety grating

Types of Expanded Metal Sheets

There are several types of expanded metal sheets, each engineered for specific applications and performance requirements. Understanding the differences helps buyers select the best expanded metal for their project, whether for industrial filtration, architectural facades, or heavy-duty flooring. Below are the most common types:

Standard (Raised) Expanded Metal Sheet

Standard expanded metal, also called raised expanded metal, is a functional and affordable product available in a wide range of materials, gauges, and opening sizes. Its raised, slip-resistant surface is ideal for industrial catwalks, stair treads, and security fencing. Standard expanded metal is manufactured from stainless steel, carbon steel, galvanized steel, and aluminum, and it is characterized by its diamond-shaped openings and elevated mesh profile. This type provides excellent structural support while maintaining ventilation and drainage.

Flattened Expanded Metal Sheet

After the initial expansion process, standard expanded metal can be further processed by a cold rolling machine to flatten the mesh. Flattened expanded metal has a smooth, even surface, making it ideal for applications that require a uniform appearance, such as architectural cladding, interior design panels, and machine guards. The flattening process reduces the mesh thickness but maintains the strength and durability of the original material. Buyers often choose flattened expanded metal for modern design projects and where smoother surfaces help in handling or assembly.

Expanded Metal Roofing Sheets

Architectural expanded metal is a cost-effective and aesthetically pleasing solution for modern architectural designs, including roofing, ceilings, and sunscreens. Available in aluminum, carbon steel, and stainless steel, expanded metal roofing sheets come in both flattened and conventional (raised) forms. They are offered in various mesh sizes, thicknesses, weights, and finishes to match diverse architectural styles and performance needs. The mesh design allows natural light penetration, improves ventilation, and adds a dynamic visual effect to building envelopes.

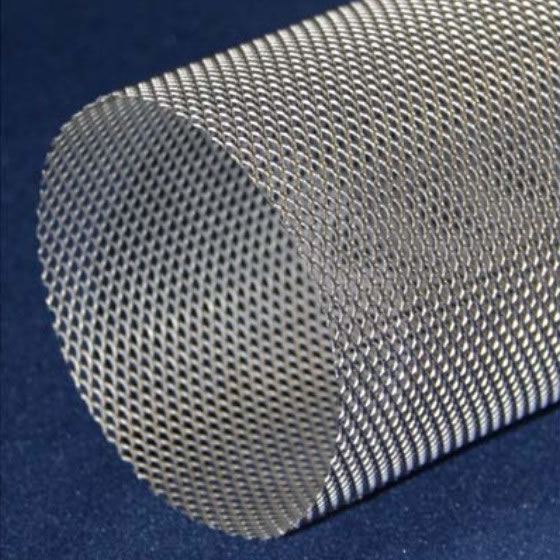

Micro Expanded Sheet Metal

Micro expanded metal is manufactured from lighter gauge metals with tiny, precision-formed openings. It is widely used for filtration, acoustic panels, EMI/RFI shielding, and speaker grilles. Micro expanded metal sheets are available in conventional, flattened, and hexagonal patterns, offering excellent strength-to-weight ratios and high open areas. Their fine mesh is suitable for delicate filtration tasks and as support for composite materials in aerospace and electronics industries.

Expanded Metal Sheet with Ribbon Mesh

Ribbon mesh is a specialized form of architectural expanded metal featuring solid bands of ribbon-like, contoured shapes integrated into the metal sheet. This design creates striking visual effects and enhances structural integrity, making it a preferred choice for decorative facades, privacy screens, sunscreens, and interior partitions. Ribbon mesh expanded metal is available in a variety of patterns, materials, and finishes, allowing architects and designers to achieve unique and functional aesthetics.

Metal Expanded Grating Sheet

Expanded metal grating is engineered for heavy-duty industrial, commercial, and architectural applications requiring robust load-bearing capabilities. This durable and cost-effective product is used in the construction of trailers, heavy-duty fencing and barriers, industrial facility floors, water treatment plants, bridge walkways, oil and gas platforms, and more. Expanded grating offers excellent traction, drainage, and ventilation, making it ideal for fire escapes, stair treads, mezzanines, ramps, and walkways. Its one-piece construction eliminates the need for welding, reducing installation time and costs.

Custom Made Expanded Metal

Custom expanded metal solutions are designed for projects that require unique shapes, mesh patterns, or dimensions not found in standard stock. Common custom shapes include circles, rectangles, oblongs, and even complex geometric designs for specialized applications. Custom expanded metal sheets are available in a range of materials such as stainless steel, carbon steel, galvanized steel, and aluminum, and can be finished with powder coating, anodizing, or galvanizing for added durability and corrosion resistance. Custom fabrication services help buyers achieve exact specifications for their unique requirements.

Common Uses and Applications of Expanded Sheet Metal

Expanded sheet metal is renowned for its versatility and is used across numerous industries, including construction, architecture, manufacturing, transportation, security, and art. Its combination of strength, durability, and open area makes it suitable for a broad range of uses. Below are some of the most common applications:

- Industrial flooring and walkways: Expanded metal grating is widely used in factories, warehouses, catwalks, and platforms due to its slip resistance and load-bearing strength.

- Security fencing and barriers: The robust mesh design provides security and visibility for perimeter fencing, gates, and machine guards in commercial and industrial facilities.

- Architectural facades and sunscreens: Expanded metal sheets serve as exterior cladding, sunscreens, and privacy screens, adding aesthetic value and functionality to modern buildings.

- Filtration and screening: Micro expanded metal is essential in air, water, and oil filtration systems, HVAC units, and sieves, where precise particle separation is required.

- Automotive and transportation: Used in automotive grilles, running boards, ventilation panels, and protective covers for vehicles and railways.

- Decorative and artistic applications: The intricate lattice pattern enables artists and architects to create three-dimensional surfaces, sculptures, and interior design elements.

- Support for construction materials: Builders use expanded metal lath to reinforce plaster, stucco, and adobe in walls and ceilings, improving structural integrity.

- Acoustic and EMI/RFI shielding: Micro expanded metal is used in electronic enclosures, speaker grilles, and acoustic panels to control sound and electromagnetic interference.

- Lighting and ventilation: The open mesh design allows for optimal airflow and light transmission in lighting fixtures, air diffusers, and louvers.

Expanded metals can be manufactured from stainless steel, brass, or aluminum, making them strong, lightweight, and chemically resistant. Their exposed edges provide enhanced traction, which is advantageous for applications such as drain covers, catwalks, and stair treads. Many objects, including conveyor pathways, braai grids, and fencing, can be made with expanded metal.

Expanded metal's intricate lattice pattern also empowers artists and architects to design visually captivating three-dimensional surfaces, which can be coated in plaster or other materials to produce dramatic artworks. Expanded metals are frequently used as exposed facades, screen materials, and even as substrates for printing photographic images to create large-scale graphics or textured surfaces that allow light to pass through the building envelope.

Benefits of Using Expanded Metal Sheets

When evaluating materials for your next project, consider the unique benefits that expanded metal sheets offer over other metal products such as perforated sheet, welded wire mesh, or woven wire mesh:

- Cost efficiency: The expansion process uses nearly 100% of the original metal, minimizing waste and reducing overall material costs.

- Strength and durability: The integral mesh structure provides superior load-bearing capability and resistance to impact, making it ideal for high-traffic areas and security applications.

- Lightweight construction: Expanded metal offers strength without excessive weight, making it easier to transport, handle, and install.

- Enhanced safety: Non-slip surfaces make expanded metal an excellent choice for walkways, platforms, and ramps, reducing the risk of accidents.

- Versatility: Available in a range of mesh patterns, sizes, and materials to suit almost any industrial, commercial, or architectural need.

- Ventilation and light passage: The open design allows for free flow of air, water, and light, supporting applications such as filtration, screening, and shading.

- Corrosion resistance: Expanded metal made from stainless steel, galvanized steel, or aluminum offers exceptional resistance to rust and harsh environments.

- Easy customization: Manufacturers can tailor mesh size, thickness, and shape to meet exact project requirements, including custom finishes and coatings.

- Eco-friendly production: The expansion process generates less scrap, supporting green building and sustainability initiatives.

How to Select the Right Expanded Metal Sheet for Your Application

Choosing the right expanded metal sheet involves considering several key factors to ensure optimal performance and cost-effectiveness. Here are some important decision points:

- Material selection: Do you need corrosion resistance (stainless steel or aluminum), high strength (carbon steel), or a decorative finish (brass or copper)?

- Mesh size and shape: What is the required open area for airflow, light, or drainage? Do you need diamond, square, or hexagonal patterns?

- Thickness and strand width: Will the expanded metal support heavy loads, or is it for lightweight screening?

- Surface finish: Does your application require a metallic look, painted surface, powder coating, or galvanizing for added protection?

- Form factor: Do you need standard sheets, coils, or custom shapes and sizes?

- Compliance and certifications: Does your project require compliance with building codes, ASTM standards, or industry certifications?

Explore Your Options:

Not sure which expanded metal sheet type is right for your project? Consider these search prompts to help you evaluate your options:

- What is the best expanded metal material for outdoor, corrosive, or marine environments?

- How does expanded metal compare to perforated metal for ventilation or filtration?

- What mesh size is optimal for security fencing versus architectural screens?

- Where can I find custom expanded metal fabrication services?

- What are the lead times for standard versus custom expanded metal sheets?

- How can I maximize slip resistance in industrial flooring with expanded metal?

Choosing the Right Expanded Metal Sheet Manufacturer

To ensure the best results when purchasing expanded metal sheets, it's crucial to partner with a reputable expanded metal sheet manufacturer. Use our comprehensive directory of expanded metal sheet manufacturers to compare suppliers, review their capabilities, and request quotes. Each manufacturer profile highlights areas of expertise, production capabilities, certifications, and available materials. Our proprietary website previewer allows you to quickly evaluate each business's specialization and value proposition.

Streamlined Sourcing and RFQ Process

Our platform enables you to contact multiple expanded metal sheet companies using a single RFQ (Request for Quote) form. This saves you time and ensures you receive competitive pricing, technical support, and lead time information directly from top suppliers. Whether you need standard, custom, or architectural expanded metal, our network connects you with manufacturers that can meet your precise specifications and delivery requirements.

Questions to Ask Potential Manufacturers

- What types of expanded metal sheets do you offer (standard, flattened, micro, grating, ribbon mesh)?

- Can you provide material certifications and compliance documentation?

- Do you offer custom fabrication, finishing, or value-added services such as cutting and forming?

- What are your minimum order quantities and typical lead times?

- Do you provide technical support for product selection and application engineering?

- Are samples available for testing and prototyping?

Frequently Asked Questions About Expanded Metal Sheets

- What is expanded metal sheet used for? Expanded metal sheets are used in industrial flooring, security fencing, filtration, architectural facades, and machine guards, among many other applications.

- How is expanded metal different from perforated sheet metal? Expanded metal is made by slitting and stretching a solid sheet, resulting in no material waste, while perforated metal is produced by punching holes, generating scrap.

- Can expanded metal be galvanized or coated for corrosion resistance? Yes, expanded metal can be hot-dip galvanized, powder-coated, anodized, or painted to enhance durability in harsh environments.

- What sizes and thicknesses are available? Expanded metal sheets are available in various standard and custom sizes, thicknesses, and mesh patterns to suit a wide range of applications.

- Is expanded metal eco-friendly? The manufacturing process generates minimal waste, making expanded metal an eco-friendly alternative to other metal products.

Get Started: Request a Quote or Learn More

If you're ready to purchase expanded metal sheets or want to learn more about the best solution for your application, contact our vetted manufacturers today. Use our easy RFQ form to request pricing, technical data, or material samples. Our team of experts can help you match the right expanded metal type—whether standard, flattened, micro, or custom—to your project's requirements.

Still have questions? Explore our in-depth guides on expanded metal mesh types, installation tips, and application-specific recommendations, or reach out directly for personalized assistance.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services