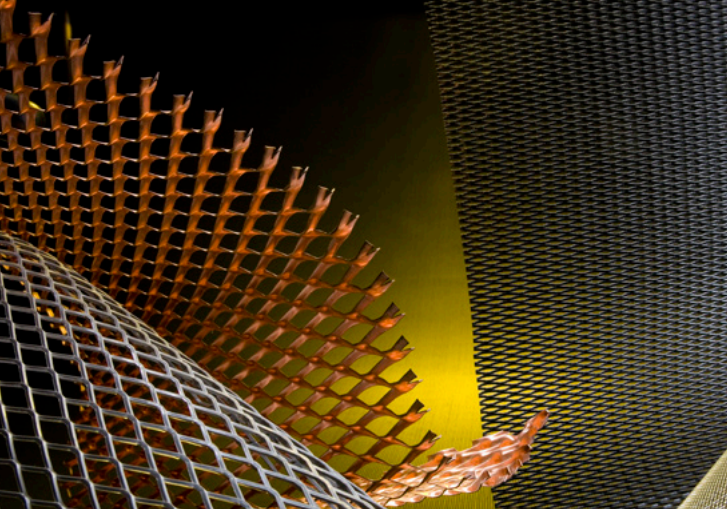

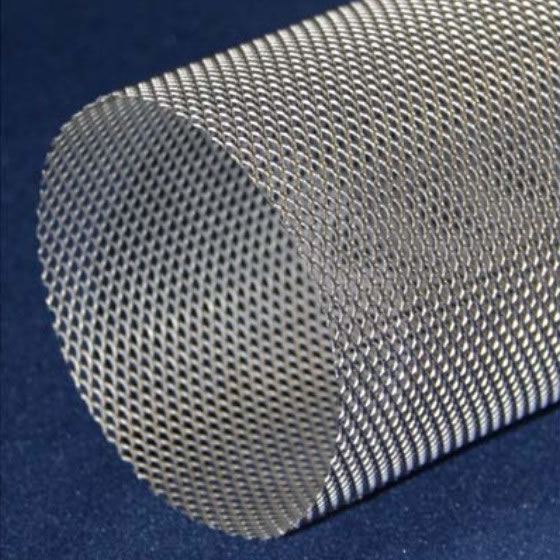

Expanded metal mesh is a kind of sheet metal that has been shaped into a diamond by being cut and stretched. These sheets have a number of tiny perforations that permit the passage of light, water, and air while also acting as a mechanical barrier for bigger items. These sheets are simple to weld and shape. Read More…

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

We sell Steel, Stainless, Aluminum, Brass, and Copper products and have the capability to process material to customer specifications. Construction supplies & services include rebars, fabrication, roofdeck, tubing, wiremesh, construction steel pipe, highchairs, bollards, grating and expanded metals.

Steel distributor specializing in beams, h-piling, channels, angles, galvanized angles, pipe & tubing, rebar, epoxy coated rebar, flats, squares, rounds, expanded metals, expanded grating, bar grating (steel, stainless, aluminum), fiberglass grating, bar joist & decking. Specialty items include NYC steel face curbing.

Midwest Steel & Aluminum is partnered with the best metal suppliers worldwide to offer our customers steel cut to size and delivered on time. We are committed to manufacturing high-quality products while pushing ourselves to be even better. We are ISO 9001:2015 certified.

More Expanded Metal Mesh Manufacturers

Expanded Metal Production for Industries:

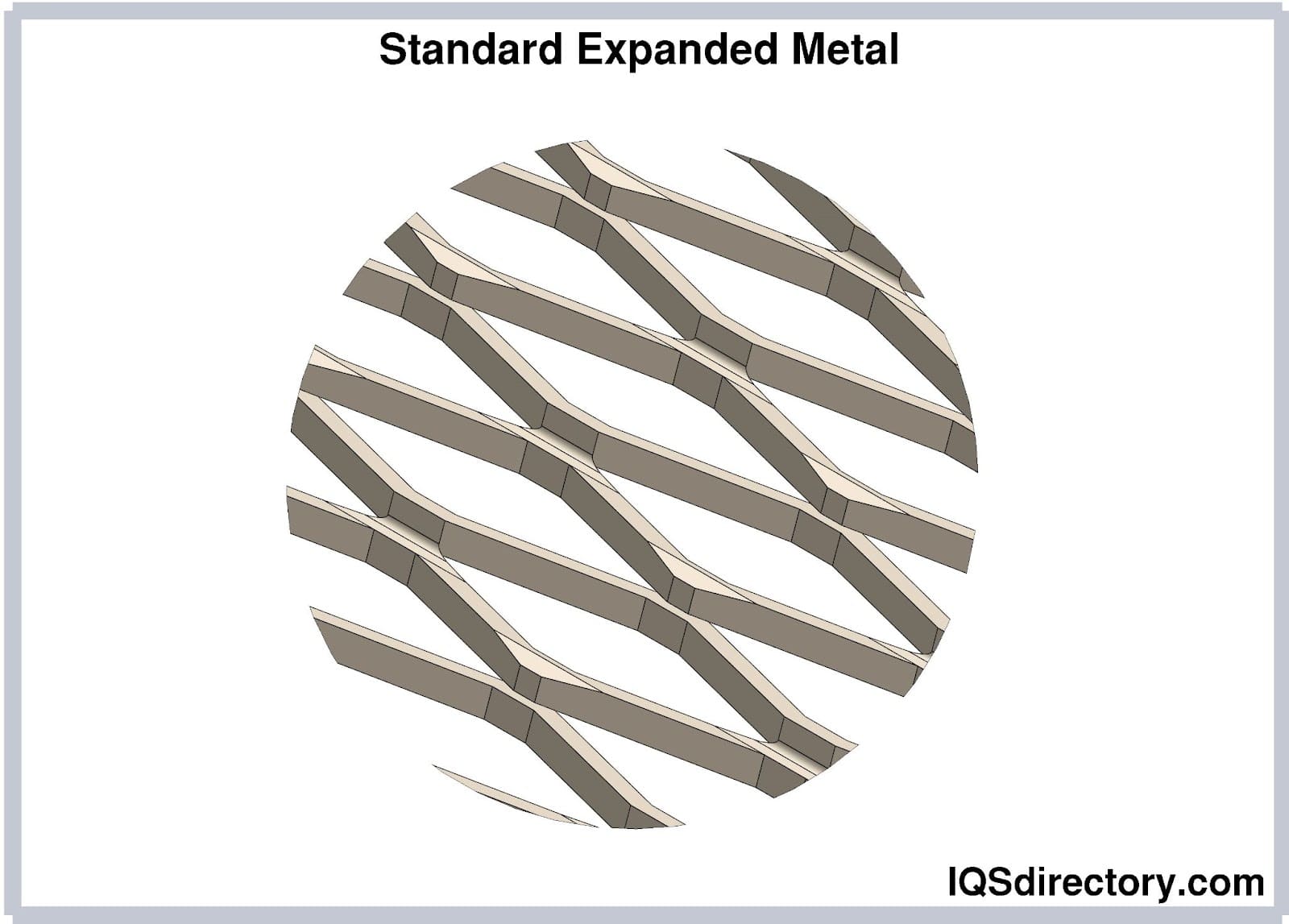

Expanded metal mesh is created using cold metal forming- a type of metal-forging technique where metals are worked at room temperature to retain or enhance the metal’s strength. This process results in apertures and regular gaps of various sizes and forms (diamond-shaped, square, and circular), allowing the passage of air, liquids, and light. Expanded metal mesh can be used to make filters or protection equipment for a variety of industrial purposes, including:

- automotive

- household appliances

- petrochemical industry

- solar energy

- chemical industry

- finished products

Characteristics of Expanded Metal Meshes for Industry:

Materials:

Expanded metal is available in mild steel, pre- galvanized steel, stainless steel (AISI 304-316-310-430), titanium, nickel, and other ductile metals.

Flattening:

A flat and smooth surface can only be obtained by flattening the expanded metal, which can be created either regularly- or irregularly-meshed patterns.

Rolls & Panels

Expanded metal mesh can come in panels and rolls. Expanded metals can undergo a variety of transformations, including the following:

- shearing- a process for removing unwanted material by slicing sheet metal

- deep drawing- a sheet metal-forming process where the metal sheet is drawn into a forming die through mechanical punch

- surface treatments- such as anodizing, powder coating, plating, etc.

- heat treatments- such as annealing or aging processes

- calendering- a process where metal sheets acquire conical or cylindrical shapes after being processed through calendar(ing) machines

- washing processes

- cutting processes,/li>

- crimping- a process of joining pieces of metal sheets together by folding the edge of a metal sheet

- multi-material injection molding

Types of Expanded Metal Mesh:

Micromesh Expanded metal

Since it has a smaller mesh size than other types of expanded metal, micro expanded metal is appropriate for use in filters as well as other applications.

Rhomboidal Expanded Metal Mesh

Rhomboidal expanded metal mesh is the most frequently used pattern with this type of material. Its unique design offers a pleasing visual look while permitting optimal air and light flow.

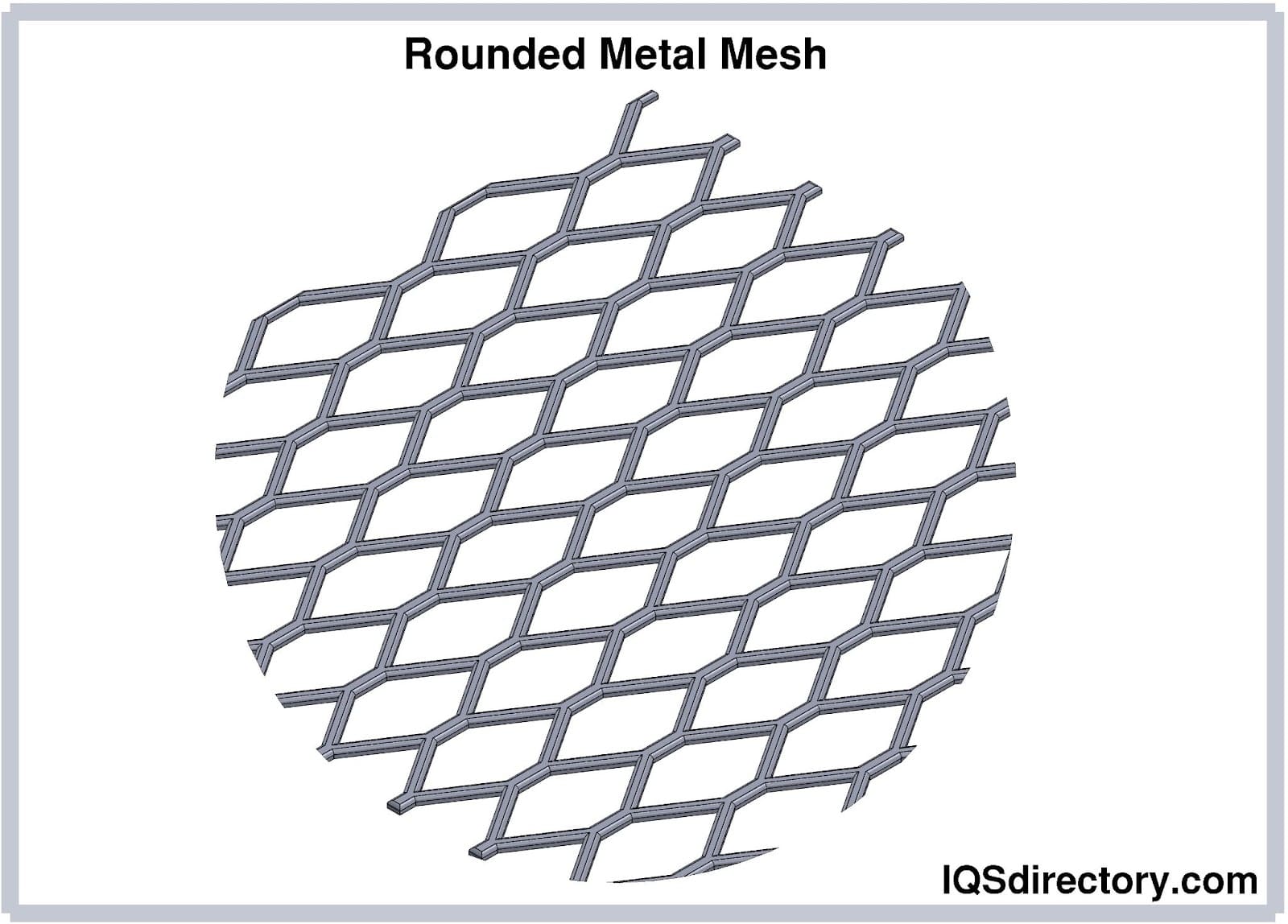

Rounded Expanded Metal Mesh

This metal mesh pattern features oval-like or circular patterns.

Square Expanded Metal Mesh

This pattern is frequently employed as screen enclosures or in filtration systems.

Hexagonal Expanded Metal Mesh

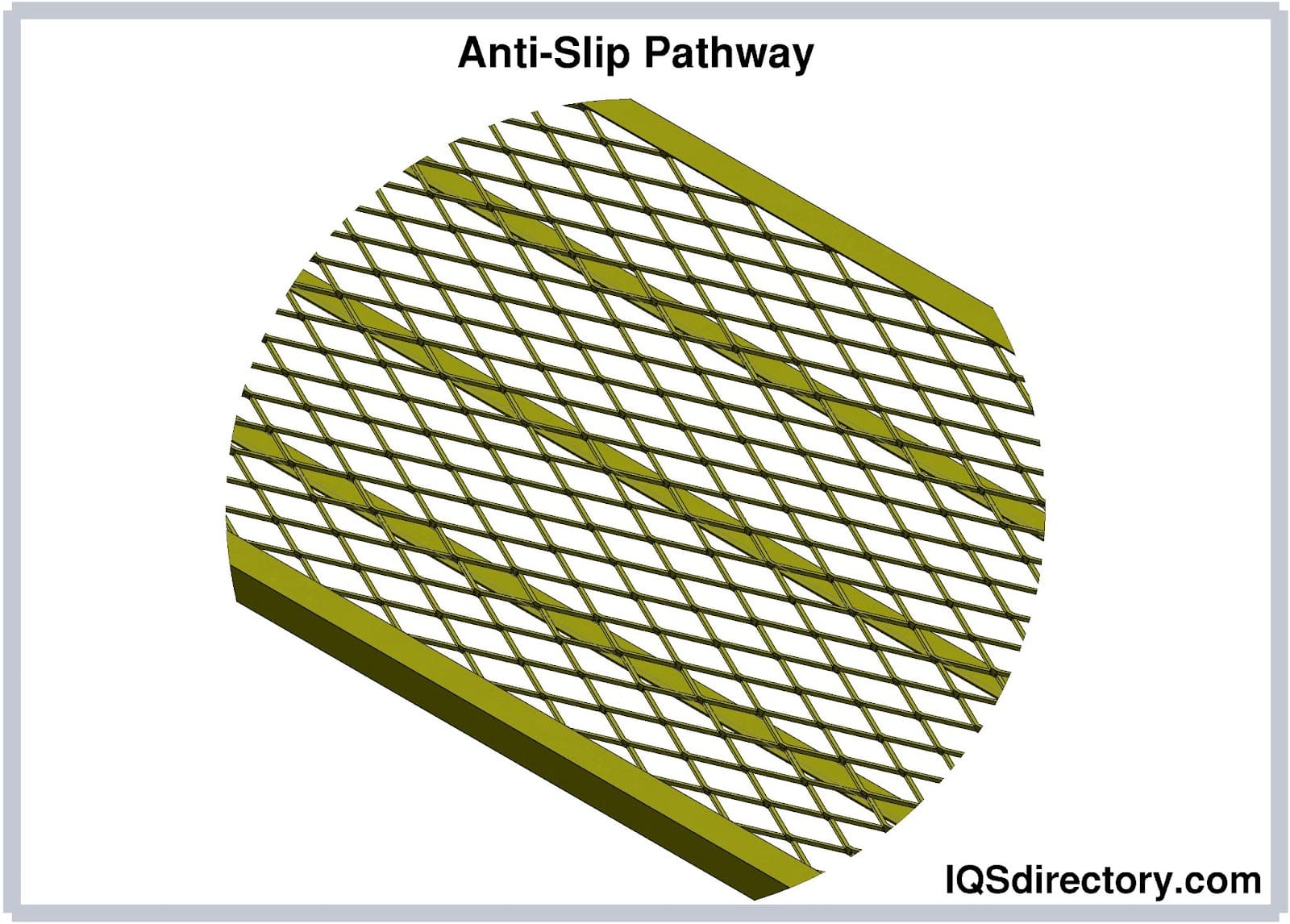

This pattern results in greater strength than other mesh patterns and is especially ideal for walkways or other areas where strength is essential.

Heavy Expanded Metal Mesh

Heavy expanded metal mesh features reinforced expanded metal and is designed specifically for heavy-duty applications.

Expanded Metal Mesh Uses:

There are numerous uses for expanded metal mesh in a number of different sectors. Some areas for which businesses have put this extraordinarily durable material to use include:

- Storage of heavy metal parts: The heaviest metal components are held in stainless-steel expanded-metal baskets by several automobile part producers and businesses in the aerospace sector as these parts are transferred from one manufacturing process to another.

- Expanded metal mesh can be integrated into the ceiling and utilized on facades and walls as well.

- Expanded metal mesh, as opposed to steel wire which would break from the impact, is utilized as industrial basket material due to its strength and ability to withstand repeated exposure to the shot peening process (a process used to modify a metal’s properties by “shooting” materials at it with enough force to create deformation) being undergone by other metal objects being housed within.

- Shot blasting parts: Similar to shot peening, shot blasting can also be used to remove impurities from a part and/or polish it while also altering the surface qualities of the part. Grade 316 expanded metal mesh is helpful to hold other metal items because of its exceptional durability, which enables it to withstand lengthy use in this high-stress application.

- Warehouse safes and other industrial containers: Expanded metal mesh has been employed as a type of fire-safe material to protect delicate items or documents in the event of a factory or warehouse fire. These enlarged metal baskets are typically constructed in layers when made specifically for this purpose, with an open outside frame to prevent heavy debris from striking the sealed containers housed inside.

Benefits of Expanded Metal Mesh

- Constructed from a single substance: Expanded metal mesh is created from a single piece of material. As a result, there are no loose strands, stressed connections, or weak welds. Expanded metal is an intrinsically robust material that may be employed in a variety of components because of its homogeneous construction.

- Expanded metal mesh is also perfect for forming and can readily go through additional processing, including pressing and shearing, because it is made from a single piece of material.

- Aesthetics: Expanded metal mesh can be used to amazing effect as decorative wall sizes and is offered in a wide variety of hues, materials, and styles.

- Less waste: Instead of punching holes out of a material, the best approach includes the slicing and stretching the material performed through expanded metal mesh. When opposed to conventional metal processing techniques like perforation which wastes raw materials, expanded metal mesh creation offers instant cost savings.

- Anti-slip passageways: Building stair treads, ramps, and walkways benefit greatly from this material's strong grip, which is provided through expanding mesh knuckles.

Choosing the Right Expanded Metal Mesh Manufacturer

To ensure the most productive outcome when purchasing expanded metal mesh from an expanded metal mesh manufacturer, it is important to compare several companies using our directory of expanded metal mesh manufacturers. Each expanded metal mesh manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each expanded metal mesh business website using our proprietary website previewer to quickly learn what each business specializes in. Then use our simple RFQ form to contact multiple expanded metal mesh companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services