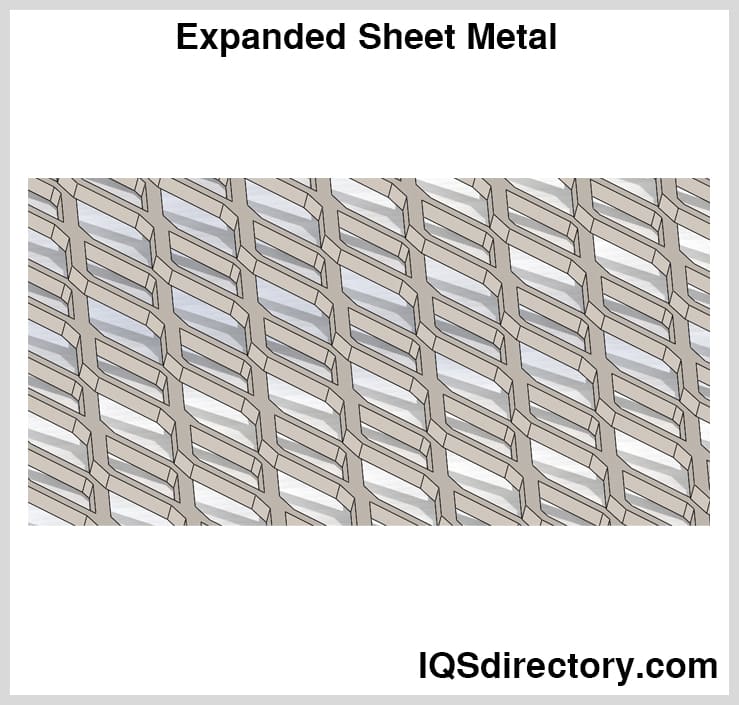

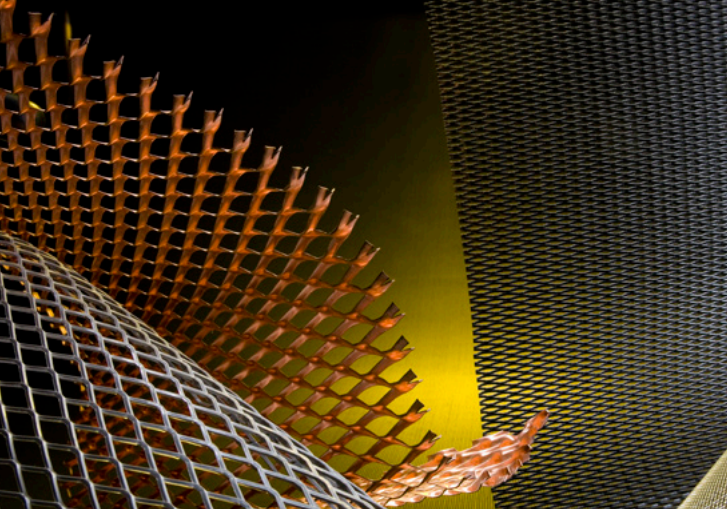

The term “expanded metal” refers to sheet metal that has been cut, stretched, and shaped into a material that resembles a metal mesh and has regular patterns, most frequently diamond shapes. There are numerous residential and commercial applications for expanded metal. Expanded metal is more durable and adaptable than many other types of sheet metal. Stainless steel, brass, or aluminum is used to make expanded metals. They are strong, lightweight, and chemically resistant. Several objects, including conveyor pathways, braai grids, and fencing, can be made with expanded metal. Read More…

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

We sell Steel, Stainless, Aluminum, Brass, and Copper products and have the capability to process material to customer specifications. Construction supplies & services include rebars, fabrication, roofdeck, tubing, wiremesh, construction steel pipe, highchairs, bollards, grating and expanded metals.

Steel distributor specializing in beams, h-piling, channels, angles, galvanized angles, pipe & tubing, rebar, epoxy coated rebar, flats, squares, rounds, expanded metals, expanded grating, bar grating (steel, stainless, aluminum), fiberglass grating, bar joist & decking. Specialty items include NYC steel face curbing.

Midwest Steel & Aluminum is partnered with the best metal suppliers worldwide to offer our customers steel cut to size and delivered on time. We are committed to manufacturing high-quality products while pushing ourselves to be even better. We are ISO 9001:2015 certified.

More Expanded Metal Sheet Manufacturers

The Process of Manufacturing Expanded Metal Sheets

Alternating patterns are used to cut a sheet of metal before stretching it out like an accordion. These sheet metals are often used to filter air or water through the sheet. Brass, Aluminum, and stainless steel are used because they have higher durability and resistance to corrosive substances.

Types of Expanded Metal Sheets

Standard expanded metal is a very functional and affordable product. It is available in the material, gauge, and opening sizes of choice. When a raised, slip-resistant surface is required, standard expanded metal sheets are perfect. Manufacturers offer standard expanded metal in stainless steel, carbon steel, galvanized steel, and aluminum.

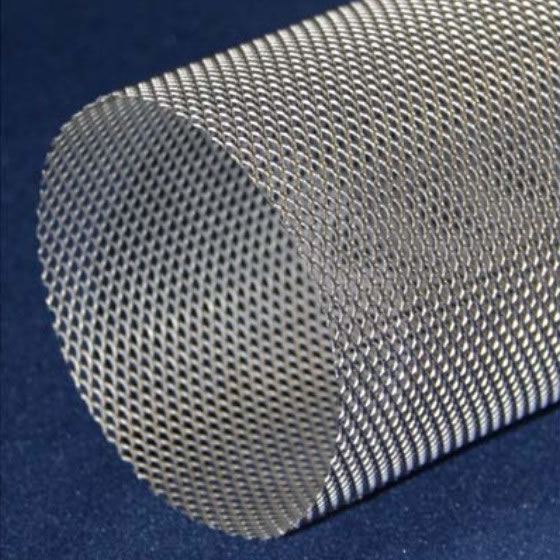

Flattened Expanded Metal Sheet

After the expansion process, the expanded metal is cold rolled via a machine that flattens the metal. For situations when a smooth surface is desired, it is the ideal option.

Expanded Metal Roofing Sheets

Almost any architectural metal project can benefit from the cost-effectiveness of architectural expanded metal. Architectural expanded metal is available in aluminum, carbon steel, and stainless steel. In flattened or conventional forms, there is a range of sizes, weights, and finishes.

Micro Expanded Sheet Metal

In addition to many other uses, micro expanded metal can be used in filters. It is made of lighter gauge metal with tiny holes. Micro expanded metal sheets come in conventional, flattened, and hexagonal patterns.

Expanded Metal Sheet with Ribbon Mesh

Ribbon mesh is architectural expanded metal with solid bands of ribbon-like contoured shapes integrated into a metal sheet. Ribbon mesh expanded metal is offered in a range of designs and materials.

Metal Expanded Grating Sheet

A range of industrial, commercial, architectural, and drainage applications use durable and affordable expanded metal grating. Extended metal gratings are used to build trailers, heavy-duty fence and barrier construction, industrial facility construction, water treatment facilities, and bridge walkways. Oil and gas platforms and affordable vertical screening, fire escapes, stair treads, mezzanines, ramps, and walkways, can all be created from grating sheets.

Custom Made Expanded Metal

Custom expanded metals are made in many unusual shapes, patterns, and sizes. The circle, rectangle, and oblong are common metal shapes. Custom expanded metal sheets are available in stainless steel, carbon steel, galvanized steel, and aluminum.

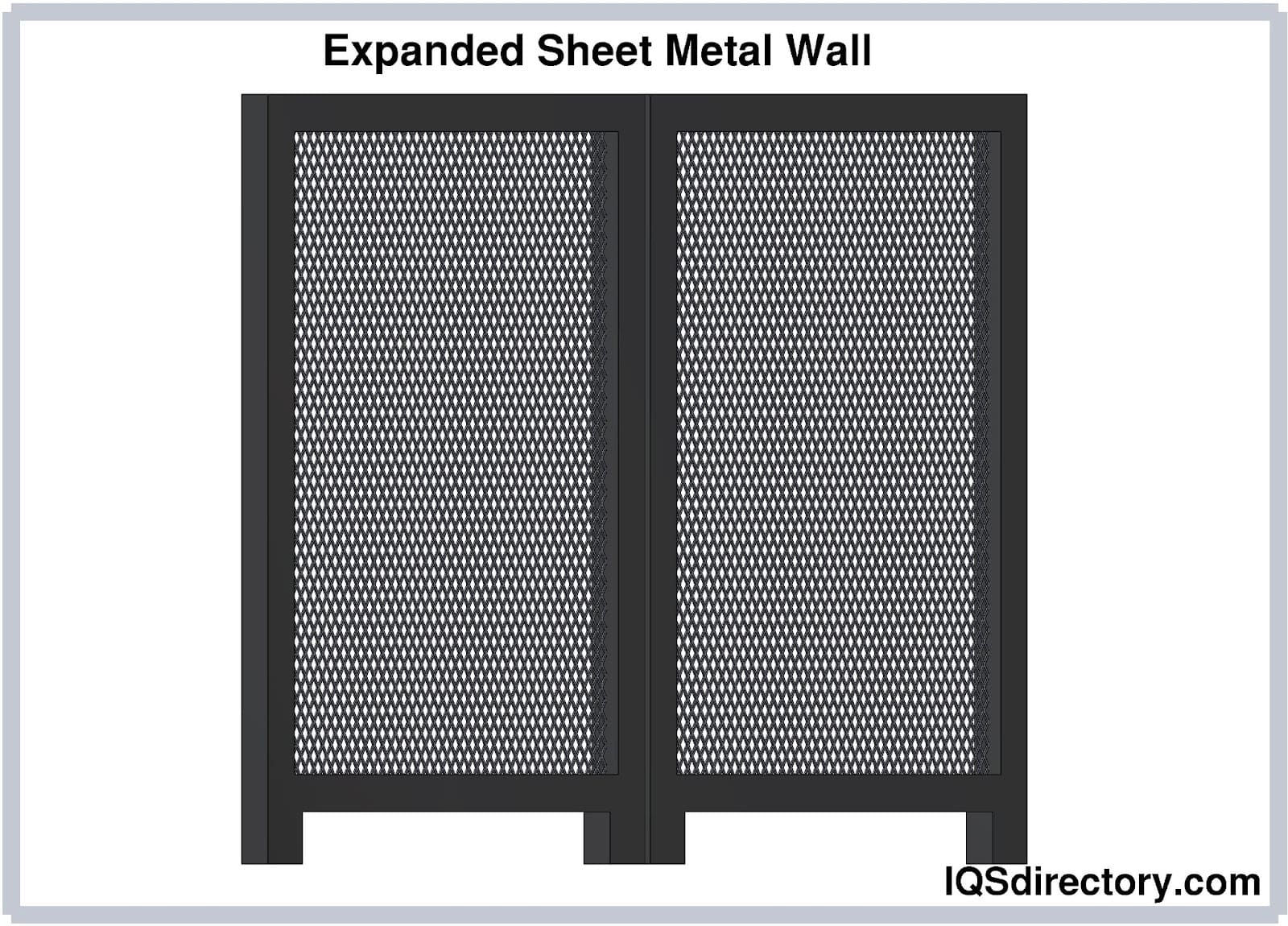

Uses of Expanded Sheet Metal

Most often, expanded metals are used to create grates, walkways, and fences. Although expensive, the material is adaptable, robust, and stronger than lighter wire mesh. Expanded metals can be utilized in any application that calls for this feature since they provide protection from heavy objects while permitting the flow of air and water. Due to its adaptability, this material is more durable than many other types of sheet metal.

- Stainless steel, brass, or aluminum are used to make expanded metals. They are strong, lightweight, and chemically resistant. Several objects, including conveyor pathways, braai grids, and fencing, can be made with expanded metal.

- Expanded metals' exposed edges also give them more traction, which is advantageous for applications like drain covers and catwalks.

- Expanded metal is used extensively in the construction industry. Builders use expanded metal as a lath to support materials like adobe, plaster, and stucco in walls.

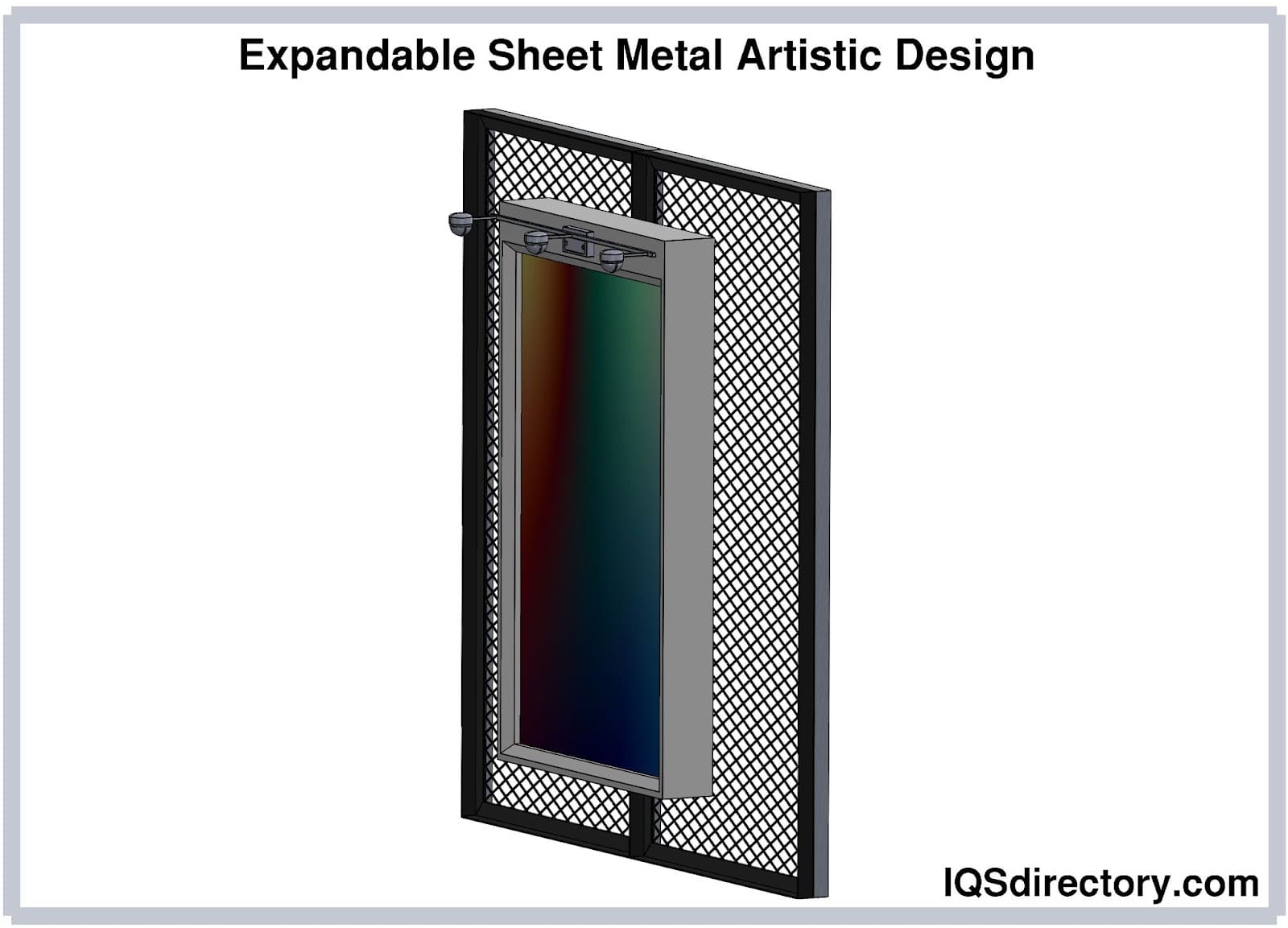

- Expanded metal's intricate lattice pattern enables artists to design intricate three-dimensional surfaces that may be coated in plaster or other materials to produce spectacular three-dimensional artworks. Expanded metals can be shaped into simple or intricate decorative shapes. They are often used by architects as exposed facades or screen materials.

- Expanded metal sheets can be printed with photographic pictures to create enormous graphic images or textures that permit light to pass through the building's outside surface.

Choosing the Right Expanded Metal Sheet Manufacturer

To ensure the most productive outcome when purchasing expanded metal sheets from an expanded metal sheet manufacturer, it is important to compare several companies using our directory of expanded metal sheet manufacturers. Each expanded metal sheet manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each expanded metal sheet business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple expanded metal sheet companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services