Stainless steel expanded metal is a metal sheet product that has been cut and stretched to create a variety of openings, typically in the shape of diamonds. While creating a beautiful or aesthetic aspect, stainless steel expanded metal offers weight and price savings compared to solid sheets of similar material and a free passage of light, sound, and air. Read More…

Our expanded metal is ideal for a wide range of applications and our teams will work with you every step of the way to guarantee your satisfaction. Our goal is to exceed your expectations and we take pride in providing our customers with outstanding services.

We sell Steel, Stainless, Aluminum, Brass, and Copper products and have the capability to process material to customer specifications. Construction supplies & services include rebars, fabrication, roofdeck, tubing, wiremesh, construction steel pipe, highchairs, bollards, grating and expanded metals.

Steel distributor specializing in beams, h-piling, channels, angles, galvanized angles, pipe & tubing, rebar, epoxy coated rebar, flats, squares, rounds, expanded metals, expanded grating, bar grating (steel, stainless, aluminum), fiberglass grating, bar joist & decking. Specialty items include NYC steel face curbing.

Midwest Steel & Aluminum is partnered with the best metal suppliers worldwide to offer our customers steel cut to size and delivered on time. We are committed to manufacturing high-quality products while pushing ourselves to be even better. We are ISO 9001:2015 certified.

More Stainless Steel Expanded Metal Manufacturers

This expanded sheet metal provides a single-piece design that won't unravel and, under normal conditions, will maintain its shape for many years. The diamond-shaped trusses' strands and bonds increase this material's rigidity and strength. There are numerous gauges, opening widths, and sheet sizes for this expanded sheet metal.

Stainless Steel Expanded Metal Manufacturing Process

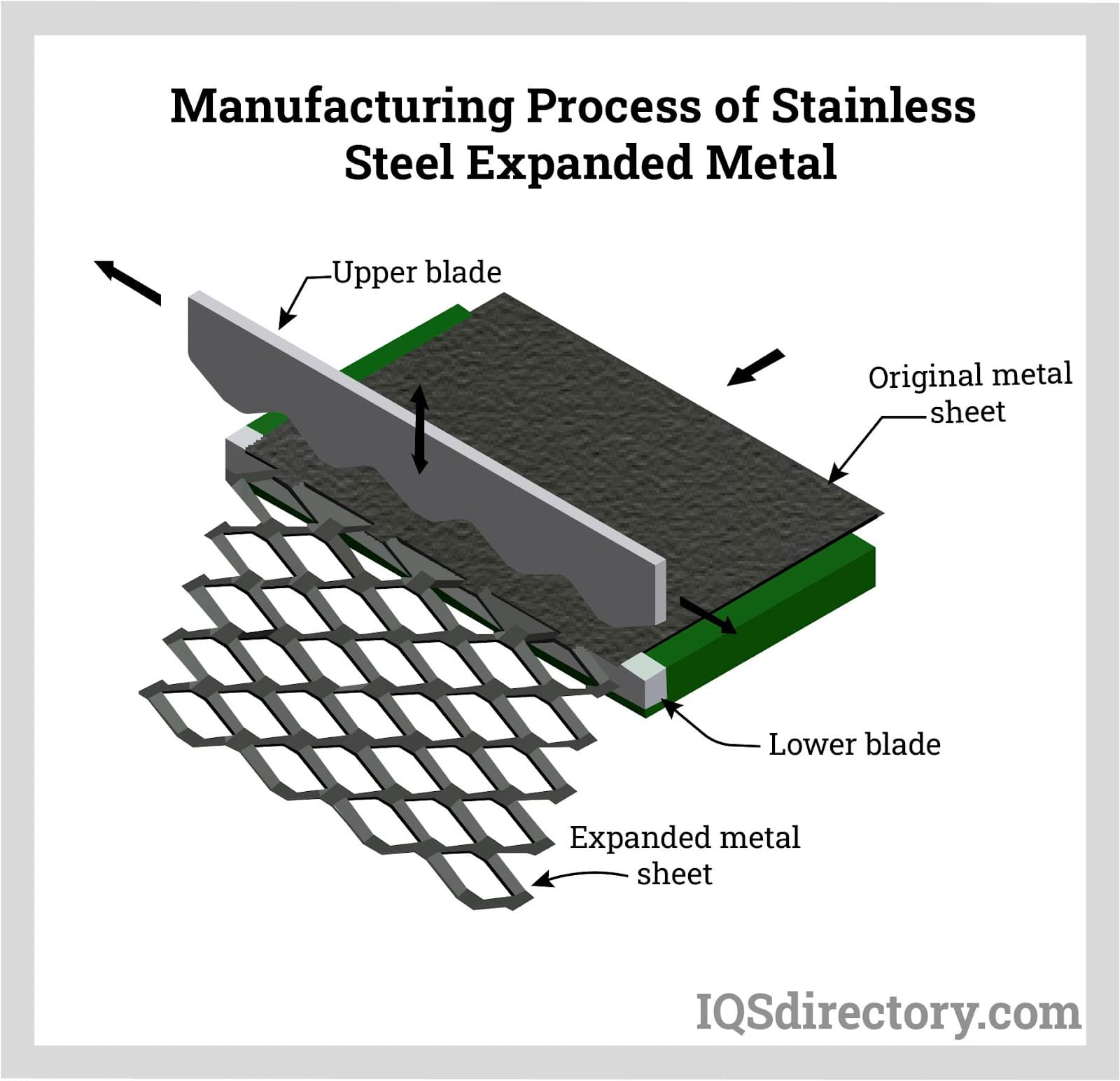

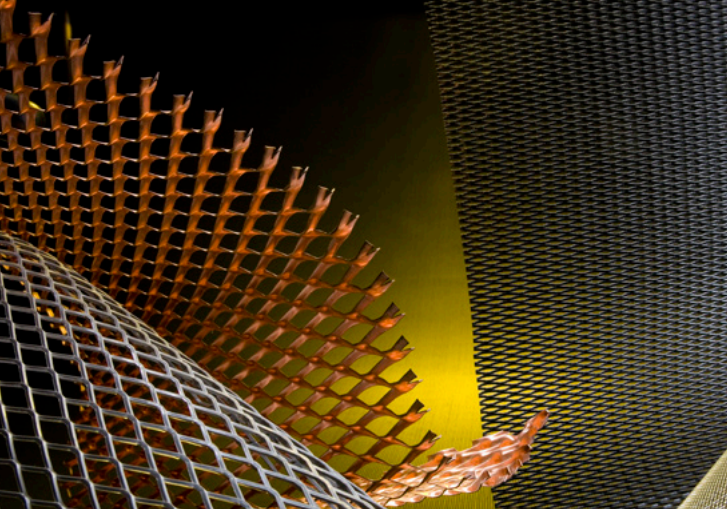

Expandable stainless steel sheets or coils create an expanded metal mesh. The manufacture of stainless steel expanded metal is depicted in the image below, where expanded metal has been created from a single piece of metal sheet.

This graphic illustrates how machines can transform a solid metal sheet into expanded metal without wasting material by slitting and stretching it using a pair of dies with an upper and lower blade. First, the stainless steel sheets or coils are fed into the expanding machine, where the metal is stretched and cut using a precision die. Next, the fabric is stretched and sheared into a specific design with consistent opening sizes. When the product is complete, the strands create gaps that provide an impenetrable barrier to large solid objects or human bodies while allowing the free passage of air, sound, liquid, and heat.

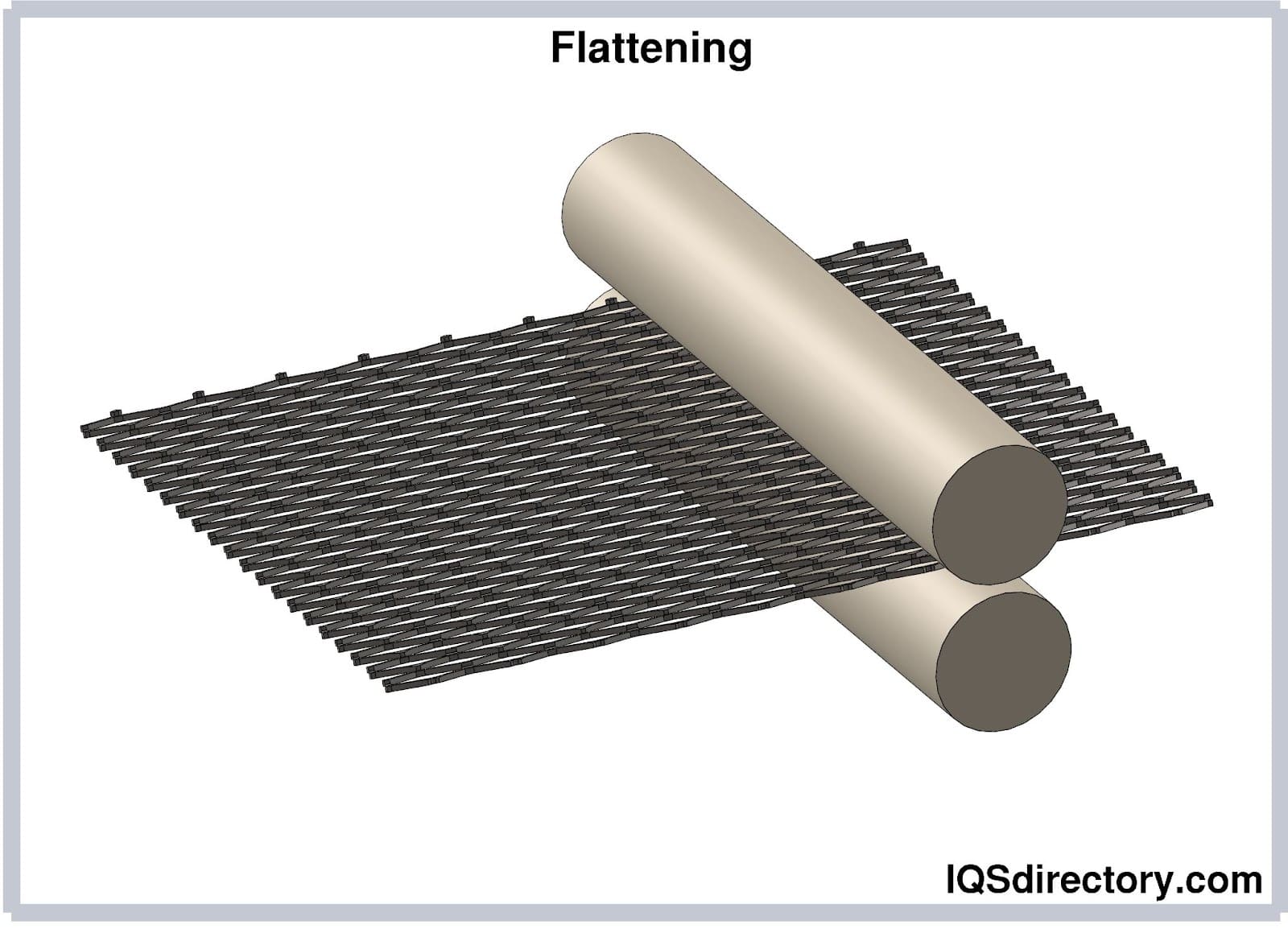

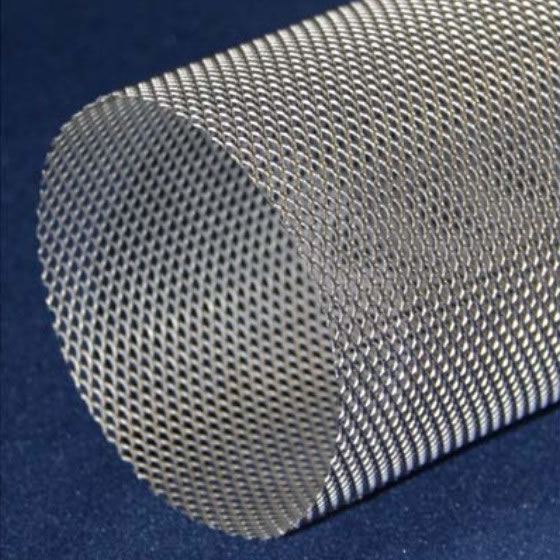

The image below demonstrates how the rolling mill creates expanded stainless steel that has been flattened. A rolling mill flattens raised stainless steel metal to where it then becomes known as a flattened expanded metal.

The resulting stainless steel sheet is stronger per pound and can be extended up to ten times its original width without losing strength. The production process results in no material loss. Due to the extended stainless steel mesh's sturdy material characteristics, it won't unravel. The surviving strand intersections help keep the finished metal sheet together even if it is sliced at one or more spots.

Applications of Stainless Steel Expanded Metal

Expanded stainless steel mesh and sheet products offer manufacturers may utilize a strong, beautiful, expanded metal product for a variety of purposes. The expanded metal's deep diamond cutouts offer a flexible solution for many applications that call for a more aesthetic or ornamental look. Expanded metal mesh made of stainless steel has many different uses in different industries.

Often, stainless steel expanded metal is converted into a basket form for use by various industries. Some uses for which businesses have put these extraordinarily durable baskets are as follows:

Heavy metal parts' storage:

Several automobile part producers and businesses hold the heaviest metal components in stainless steel expanded metal baskets.

Washing enclosed material:

The aerospace sector and other industries needed an efficient way to clean materials and equipment as they were transferred from one process to another while still being kept enclosed in containers. They found their solution through stainless steel expanded metal baskets. The higher strength and lighter weight of this material provided extra benefits.

Marine applications:

Due to stainless steel's ability to tolerate exposure to salt-enriched environments and its strength, this material is more than able to house items facing such conditions. Stainless steel expanded metal may also be found as fencing and security partitions, as part of filtration systems, and even as building facades in such climates.

Other applications for expanded metals made of stainless steel include:

- Shot peening enclosures

- Factory & elevator flooring

- Walkways

- Industrial applications

- Caging

- Machine and equipment enclosures

- Art material for 3D sculptures

- Perimeter fencing

- Construction rigging

- Steps

Expanded Stainless Steel Features & Benefits

Regardless of the application, expanded mesh and sheet materials offer tested quality. Manufacturers can utilize expanded sheet metal for applications ranging from security applications to protect assets to new-era architectural concepts used to enhance the appeal of a space or work of art because of its inventive design and lightweight. Other advantages and qualities of this expanded metal include:

- Versatility

- Durability

- One-piece construction

- Excellent strength-to-weight ratio

- Easy cutting and shearing

- Ventilation properties

- Economical, compared to solid sheets of stainless steel

- Attractiveness

- High melting point

Disadvantages of Expanded Stainless Steel

- Although expanded stainless steel's high melting point can be a significant asset in some situations, welding is difficult, placing restrictions on this material in building applications.

- Additionally, stainless steel expanded metal is not the most economical metal. This material is used so infrequently in some industries because it is more expensive to produce than other materials.

- Although less significant than the drawbacks above, stainless steel is also susceptible to stains. Even though cleaning stainless steel is a simple operation, it sometimes looks continuously dirty since it readily shows even the smallest smudge or fingerprint.

Choosing the Right Stainless Steel Expanded Metal Supplier

To ensure you have the most beneficial outcome when purchasing stainless steel expanded metal from a stainless steel expanded metal supplier, it is important to compare several companies using our directory of stainless steel expanded metal suppliers. Each stainless steel expanded metal supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each stainless steel expanded metal business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple stainless steel expanded metal companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services